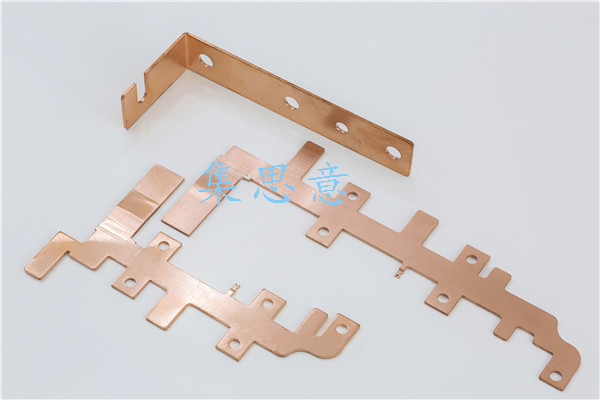

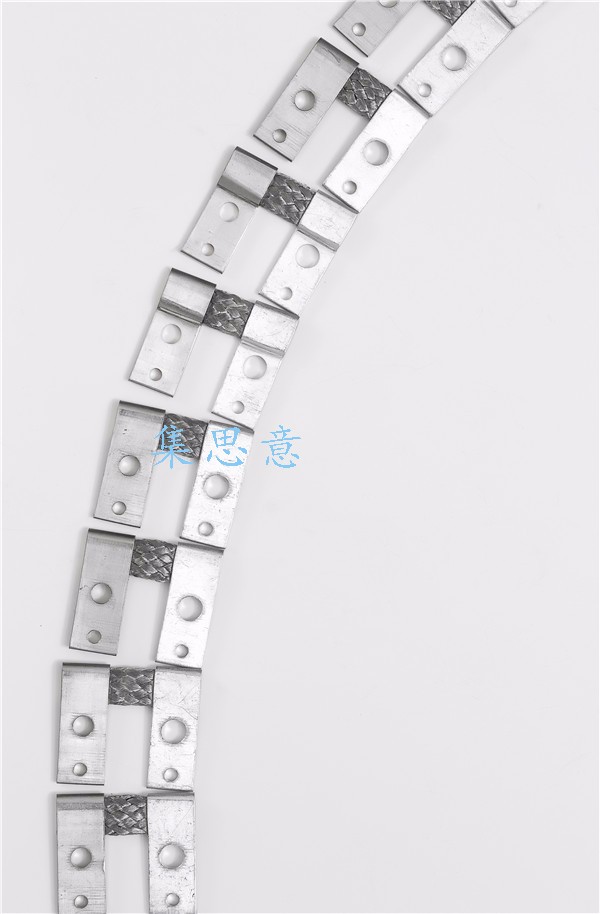

Copper sheet soft connection process

Views: Addtime:2022-06-18

Copper flexible connection is widely used in various generators, transformers, switches, buses, electrolysis, smelting and other high current electrical equipment for flexible conductive connection.

Copper sheet soft connection process:

1、 Pressure welding is to superimpose copper strip (foil) on - and use molecular diffusion welding for hot pressing; According to the characteristics of the product drawing, there are two processes: pressure welding and silver brazing;

2、 Brazing is to superimpose copper strips (foils) on - and then use molecular diffusion welding for hot pressing, and then use silver based brazing to butt weld the soft connection with the copper conductive block.

3、 Material processing range:

Thickness of copper strip (foil): 0.03mm to 0.3mm

Width of copper strip (foil): 10mm to 300mm

Copper sheet soft connection process:

1、 Pressure welding is to superimpose copper strip (foil) on - and use molecular diffusion welding for hot pressing; According to the characteristics of the product drawing, there are two processes: pressure welding and silver brazing;

2、 Brazing is to superimpose copper strips (foils) on - and then use molecular diffusion welding for hot pressing, and then use silver based brazing to butt weld the soft connection with the copper conductive block.

3、 Material processing range:

Thickness of copper strip (foil): 0.03mm to 0.3mm

Width of copper strip (foil): 10mm to 300mm